DESCRIPTION

Technical Description

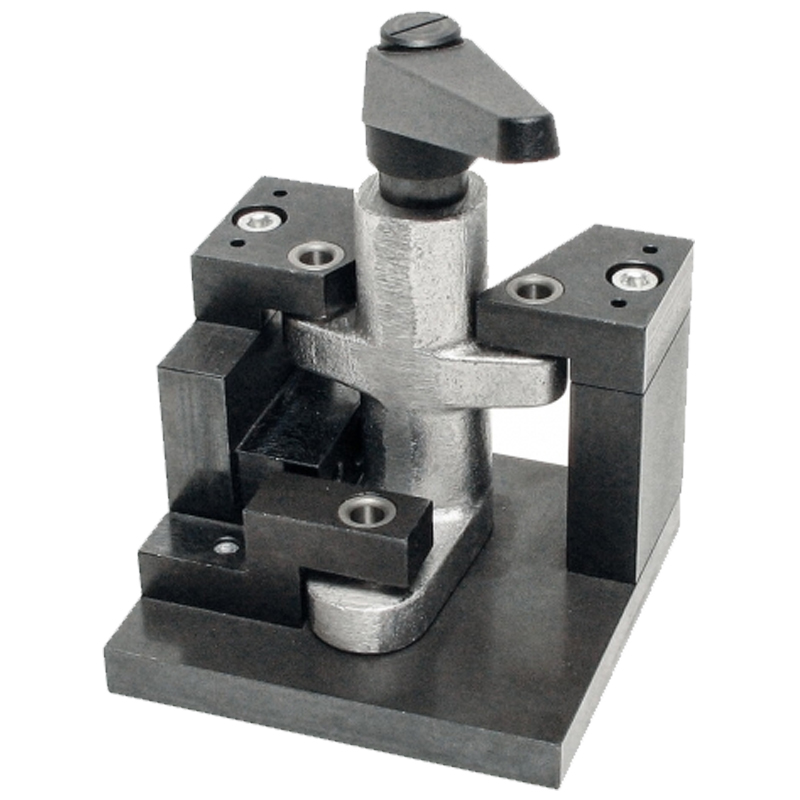

The model comprises two elements: the actual drilling jig and a cast part representing the workpiece. The cast part is to be drilled with four through-holes using a standard drill. It is clamped in the jig and the drill is fed to it by way of bushes.

Core didactic aspects are reading and understanding technical drawings, standardised and production-oriented dimensioning of parts, sketching of suggested improvements or required parts. In addition, many other aspects can be covered with the aid of this interdisciplinary teaching model, including: jig geometry, cast parts, clamping techniques, and manufacturing technology.

Learning Objectives / Experiments

Learning Objectives / Experiments

Technical drawing:

- familiarisation with three-dimensional views

- production-oriented and standardised

representation of components

- surface finish and tolerance specifications

- overview drawing, parts list

- standard parts

- 3D views

- material specifications

Technology:

- jig and clamping techniques

- manufacturing methods

- work planning

FEATURES

Technical Description

The model comprises two elements: the actual drilling jig and a cast part representing the workpiece. The cast part is to be drilled with four through-holes using a standard drill. It is clamped in the jig and the drill is fed to it by way of bushes.

Core didactic aspects are reading and understanding technical drawings, standardised and production-oriented dimensioning of parts, sketching of suggested improvements or required parts. In addition, many other aspects can be covered with the aid of this interdisciplinary teaching model, including: jig geometry, cast parts, clamping techniques, and manufacturing technology.

Learning Objectives / Experiments

Learning Objectives / Experiments

Technical drawing:

- familiarisation with three-dimensional views

- production-oriented and standardised representation of components

- surface finish and tolerance specifications

- overview drawing, parts list

- standard parts

- 3D views

- material specifications

Technology:

- jig and clamping techniques

- manufacturing methods

- work planning