DESCRIPTION

Technical Description

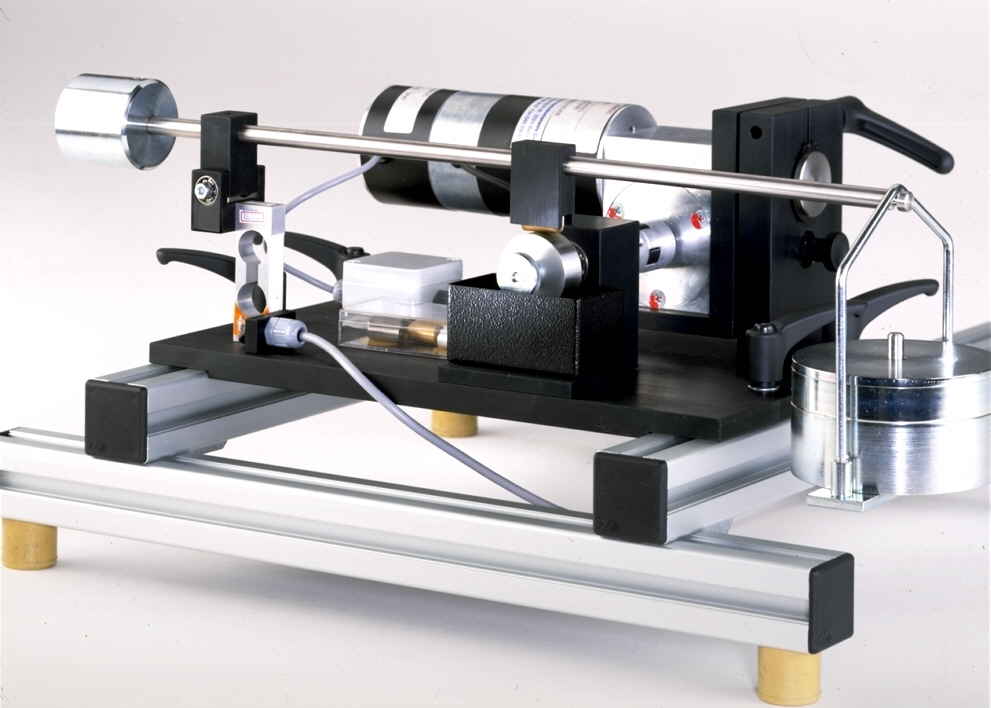

Using this instructional unit, investigations are performed on wear. The unit is intended for operation with the basic module TM 260. A dog coupling transmits the force from the drive unit. For the experiments, pins made of various materials rub against the external surface of a rotating disc under varying lubrication conditions. Initially a point contact is formed, as the wear increases, this changes to a surface contact. The friction wheel is made of hardened stainless steel, the surface is ground. There is a container for lubricant underneath the friction wheel. The pins are loaded using a lever with weights. The friction forces are measured with the aid of a full bridge strain gauge on the lever joint.

Learning Objectives / Experiments

Learning Objectives / Experiments

- Friction force as function of the pairs of friction materials

- Friction force as a function of the relative speed of the components

- Friction force as a function of the lubrication conditions

- Wear as a function of the friction parameters

FEATURES

Specification

[1] Benchtop experiment on the investigation of wear on different pairs of friction materials and lubrication conditions, operation in conjunction with the TM 260 module

[2] Stainless steel friction wheel, hardened and polished, diameter 40mm

[3] Friction pins made of steel, brass, Al

[4] Adjustable operating speed

Technical Data

Load measuring range: 0...50N

Operating speed: 0...0.42m/s

Friction wheel

- diameter 40mm

- stainless steel

Friction pins

- diam. x l: 10x20mm

- material: steel, brass, aluminium

Dimensions and Weight

l x w x h : 590 x 180 x 160 mm

Weight : approx. 8 kg

Scope of Delivery

1 experimental module, complete

1 instruction manual