DESCRIPTION

Technical Description

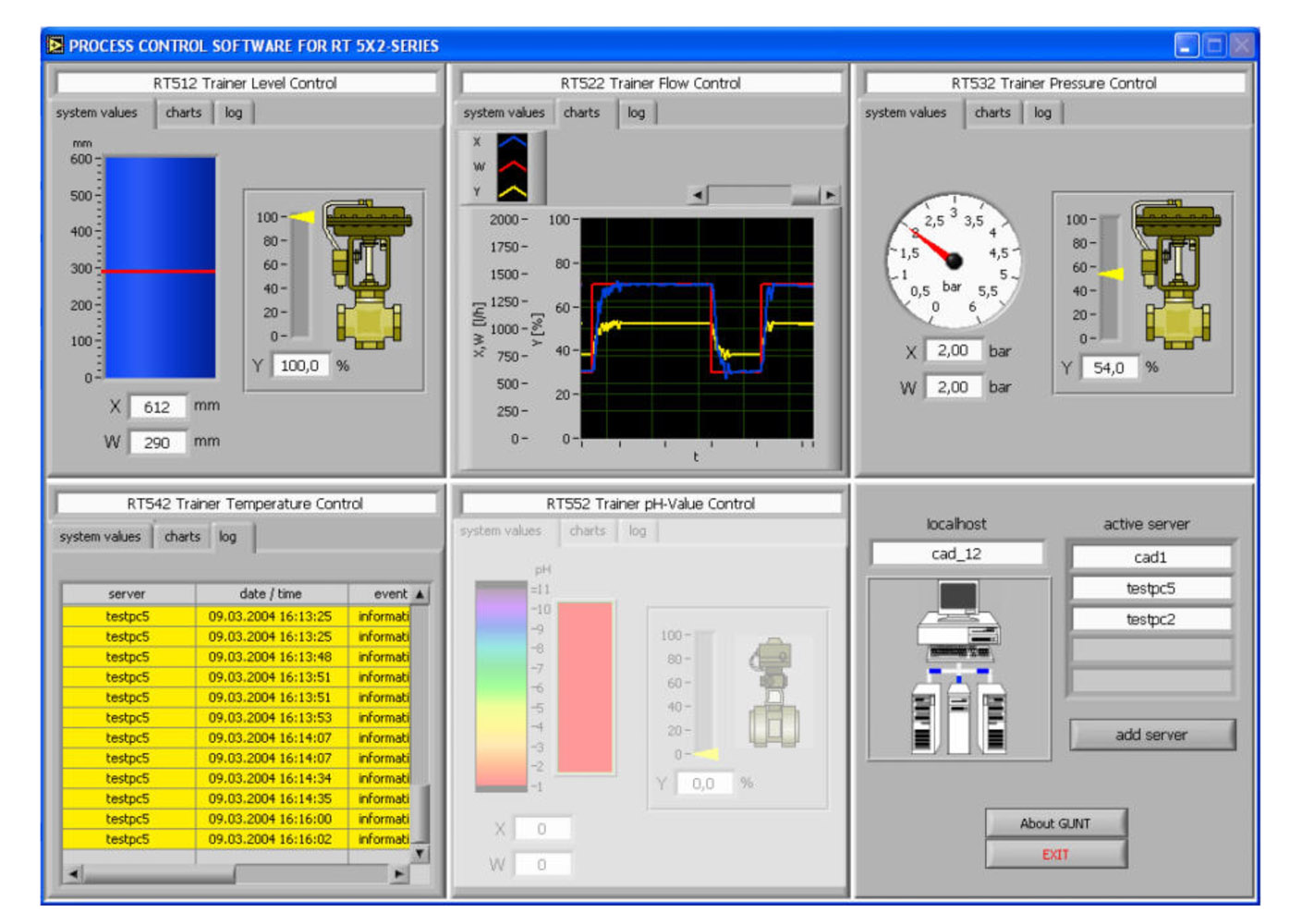

The RT 650.50 process control software (SCADA) was developed specially for the RT 512 - RT 552 series of trainers. It can automatically detect which units are connected for operation. Up to five units can be connected simultaneously. The program and the trainers communicate via Profibus DP modules. Changes to the software are transmitted to the controller of the relevant trainer.

Alongside the process schematic, controller configuration and recorder functions, the software also provides programmer, messaging and control station functions. The process schematics display the process variables and the reference, controlled and manipulating variables in real time. They also allow the reference variable, the controller parameters and controller mode to be changed. There are also status displays for the alarms.

The "Charts" menu item offers features including controller parameter setting and mode selection, setting of the reference variable and limit values for the alarm function, as well as display of the controlled and manipulating variables. The characteristic of the reference variable over time (e.g. step input, ramp etc.) is specified in the programmer. A total of three programs are available, each with 15 software modules, and each including their own custom controller parameters. The messages are divided into alarms (status indicators, over/under limit) and information (status monitoring, approaching the limit). The message status is colour-coded. The control room function permits simultaneous monitoring and, where appropriate, accessing of all connected trainers.

Learning Objectives / Experiments

- familiarisation with and use of a process control system

Stand-alone operation with a single trainer

- process schematics with online display of all process variables

- alarm function with logging

- parameterisation for the individual controllers

- manual or automatic controller mode

- controller configuration for temperature control (continuous / 2-point / 3-point controller)

- software system allows multiple trainers to be controlled/monitored from one PC

- mode of operation of a programmer additionally in combinations of multiple trainers on one PC

- control station function

- autonomous detection of the connected units

FEATURES

Specification

[1] interactive, menu-driven process control software (SCADA) for operation and monitoring of control processes

[2] control station function for simultaneous operation of multiple trainers

[3] alarm function

[4] programmer

[5] display of relevant data on PC

[6] data communication via Profibus DP

[7] use together with Profibus card RT 650.12; one Profibus card RT 650.12 per PC workstation required

Technical Data

Operation and parameterisation of hardware controllers

Recorder function with data saving

- recording and saving of time functions

- evaluation of step responses with automatically generated inflectional tangent

Language selection

- 4 pre-selectable languages

- 1 user-defined language possible

Programmer

- up to 3 programs with 15 values in each

- custom controller parameters for each program

- looping possible

Alarm function with 4 programmable values

- upper and lower alarm limit

- upper and lower message limit

- comments about alarms/messages can be entered

Software basis: LabVIEW

System requirements: Windows Vista or Windows 7

Scope of Delivery

1 CD with LabVIEW process control software

1 manual with description of software functions and instructions for use with control engineering trainers RT 512 - RT 552