GL 430 Assembly control gear

FEATURES:

- Flexible and robust assembly system for mechanical drive systems

- Practical orientation based on use of standard components

- Quick and easy assembly with no jigs and fixtures, just simple tools

- Safe drive with hand crank

- Comprehensive well-structured instructional material

DESCRIPTION

Technical Description

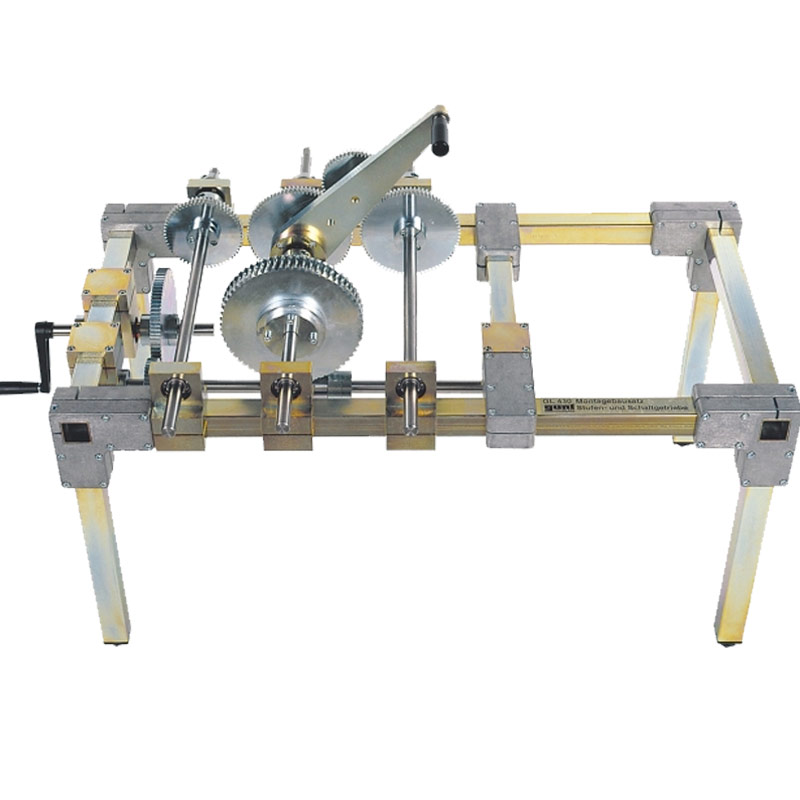

This laboratory system is used to familiarise students with the design and correct assembly of step and shift gears. The programme of exercises enables familiarisation with six different drive implementation and analysis methods: understanding the brief and the drawing, assembly, setting, adjusting, testing, and making calculations.

The flexibility of the setup and the modularity of the components simplifies experimentation and implementation of the students' own ideas.

A robust tubular steel frame with a square profile and bearing elements provide the accuracy for the setting of precise gearing. All the system components are kept ready to hand and well protected in a storage system.

The multi-step and shift gears in GL 430 are based on those of a conventional lathe. The step gear unit is very similar to the primary drive on a pillar drill.

GUNT offers three kits in this product series, each focussing on different aspects: GL 410, GL 420 and GL 430. Each kit is used entirely independently of the other kits within the series.

Learning Objectives / Experiments

- familiarisation with key components and types of mechanical drive systems

* cone pulley drive

* sliding gear unit

* quick change gear unit

* tumbler gear unit

* change gear train

* cam box (drop worm)

- calculations on mechanical drives

- practical setup of various drives, linked to simple configuration and alignment exercises

- reading and understanding engineering drawings, familiarisation with technical terminology

FEATURES

Specification

[1] demonstration and experimental kit for laying out and assembling 6 different step and shift gear units

[2] cone pulley drive

[3] sliding gear drive

[4] quick change gear

[5] tumbler gear

[6] change gear train

[7] cam box (drop worm)

[8] hand operation with crank

[9] usage of standard industrial parts

[10] solid universal frame manufactured from square steel tube

Technical Data

Spur gears

- z=24, 30, 36, 40, 45, 50, 60, 76, 80, 95

- m=2mm

Worm drive

- worm: z=6

- worm gear wheel: z=62, m=3,15mm

Dimensions and Weight

LxWxH: 1000x500x500mm (assembled frame)

Weight: approx. 80kg

LxWxH: 600x400x120mm (storage system)

LxWxH: 600x400x170mm (storage system)

Scope of Delivery

1 base frame

1 crossbar

8x bearing block, single, 1x bearing block, double

1x pendulum ball bearing, 1x drop worm

1 set of drive elements, consisting of

- 6 V-belt pulleys, 1 V-belt

- worm gear, bored worm

- 10 gear wheels

- swing lever, reversing lever, gear change

mechanism

- 3x bearing flange

- change gear axle

- 3x shaft

- 2 shafts with square shaft end

- hand crank, 4 handles

- set of small items (bolts, nuts, washers, spacer bushes, clamp rings, reducer bushes, featherkeys, pressure springs, ball bearings, pins etc.)

1 set of assembly tools

2 storage systems with foam inlay

1 set of instructional material, consisting of

technical description of system, complete set of drawings with individual parts and parts list, description of assembly processes, specimen calculations