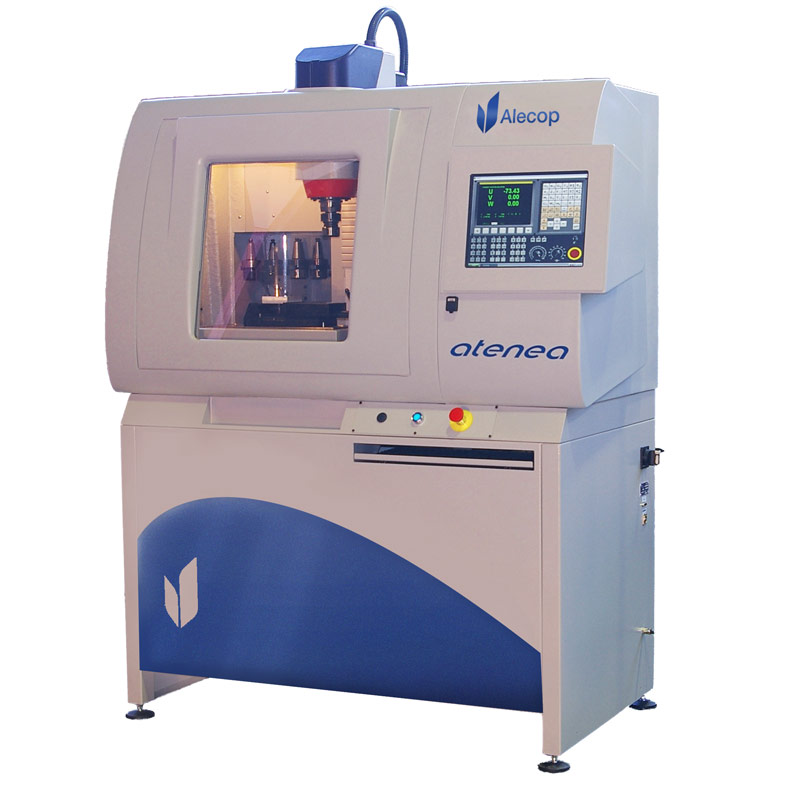

Atenea Milling machine

Standard configuration

- Vertical lathe with incorporated safety devices.

- PC, touch screen and keyboard (Wincontrol software installed).

- User’s and practical manuals.

- Control software for PC.

Optional accessories

- 8 position tool changer.

- Part securing devices (manual or pneumatic jaws).

- ISO-30 tool holder cones. Collets and mills.

- Support table for the machine and the PC.

- Cooling system.

- Silent compressor.

- Edition and simulation Software: Winunisoft.

DESCRIPTION

CNC industrial machining centre for training with integrated PC control

This is a vertical milling machine, controlled by an integrated PC, ATENEA goes one step further in bringing our training equipment closer to today’s industrial world.

The integrated PC controlling the machine has multi-control software and a touch screen to provide a close-to-reality experience while remaining a safe, informative training solution for students. Optional inclusion of relevant accessories can turn the unit into a full machining centre that can be integrated into a flexible system.

Multi CNC

Programación y visualización de simuladores FAGOR, SIEMENS y FANUC. PC, pantalla táctil y teclado incorporados.

Wincontrol multi-CNC PC control software

The program allows the user to simulate and execute the machining of a CNC programme, ISO code edited or defined by a CAD/CAM system, analysing the errors that may occur in this. The machine control is carried out through a realistic simulation of the control panel (FAGOR, SIEMENS, FANUC) with which the user is working. The main features of the programme are:

- Assisted creation of new projects customised for the chosen control.

- Graphic help menu for programming all ISO functions supported by the chosen control.

- Control of the machine drives.

- Execution of programs in automatic mode or single block.

- Simulation of different tool geometries.

- Simulation in various 3D views of the work-piece, tool and paths.

- Section of the work-piece from different angles.

- Selection of different colours for the different tools.

- Collision detection of the tool and the handle with the part and the jaw chuck.

- Printing of all the data, the CNC programme and the graphic representations.

To all of these features we must also include the high quality graphics that contribute to the speedy understanding of the simulated machining and to the clear detection of errors.

FEATURES

Technical characteristics

Axes

- Double-nut, pre-tensioned ground spindles, IT5 quality.

- Linear guide rails with ball recirculation.

- 1.8º step motor.

Head

- High precision bearings with 2 rows of angular contact balls.

- Max. torque: 7 Nm at 2000 rpm.

Guard

- Pneumatically operated

| Longitudinal X travel | 200 mm |

| Transversal Y travel | 200 mm |

| Vertical Z travel | 200 mm |

| Measurements of the work table | 450 x 180 mm |

| Maximum spindle-table distance | 320 mm |

| Spindle motor | Three-phase asynchronous 1,5 Kw |

| Spindle taper | ISO 30 |

| Spindle motor rotation speed | 100-4000 rpm |

| Axes advance motors | Step 200 ppv |

| Maximum advance of axes | 2500 mm/min |

| Electronic resolution | 0,0025 mm |

| Door opening | Automatic |

| Supply voltage | 220 V 50/60 Hz |

| Dimensions of machine | 1460 x 910 x 1870 mm |

| Approximate weight | 400 kg |