ADA 304 ECU ELECTRONIC CONTROL UNIT

Skills to be developed

- Analysis of how the electronic injection control unit works on an ECU- Motor.

- Analysis of the ECU input signals.

- Analysis of the ECU output signals.

- Testing electrical/electronic signals with without voltage and under voltage.

- Handling of auto-diagnosis tools: DD-Car.

- Fault Diagnosis: Broken sensor, failure in the communication bus (CAN-LIN), etc.

- Testing of sensors and actuators using an autodiagnosis tool.

- Instrumentation handling: Oscilloscope, Polymeter.

Equipment composition

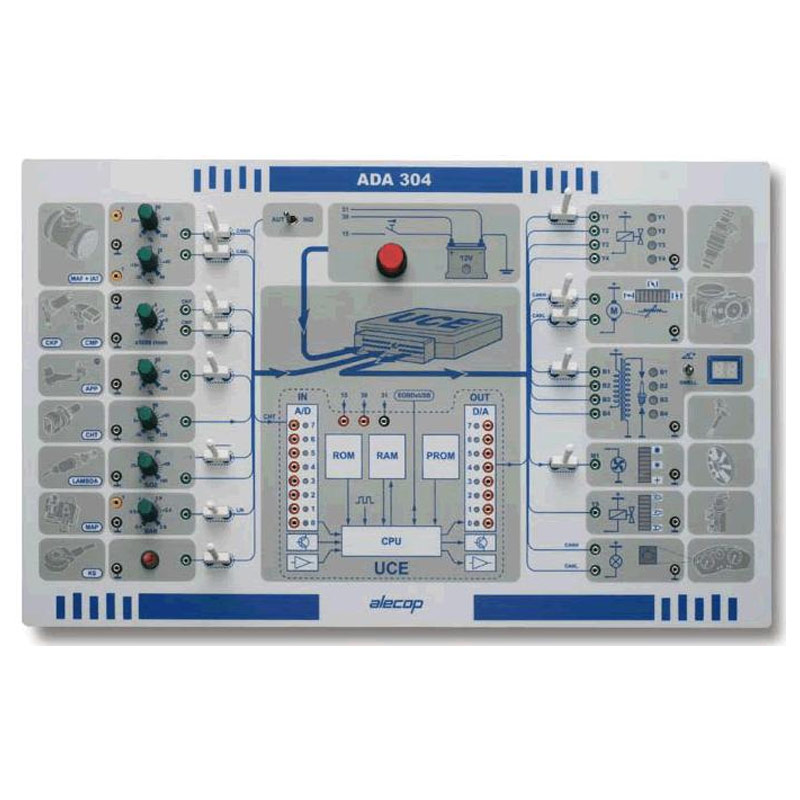

- ADA304 Panel.

- User manual.

- Practise activity manual.

- DD-Car auto-diagnosis software.

- Accessory Store.

Contents to be studied

- ECU Sensor inputs: types, characteristics etc.

- Actuator outputs from the ECU: types, characteristics etc.

- Internal architecture of an electronic control unit.

- Working of an electronic injection control unit, injection control algorithms.

- Injection time and ignition time (ignition angle and DWELL angle).

- Types and characteristics of sensor/actuator signals: Analogue, digital, multiplexing buses (CAN and LIN).

- Auto-diagnosis in electronic injection systems, failure EOBD codes.

- Reprogramming (Flash) of the electronic control unit.

- Digital /Analogue and Analogue/ Digital conversion.

DESCRIPTION

Ref.: 9EQ304AA6C – 230 V

Ref.: 9EQ304AA3C – 115 V

Equipment to study how the electronic control unit (ECU) of a petrol engine works with a multipoint sequential injection system and static ignition. The equipment enables, by means of a series of potentiometers, different operation conditions to be simulated (amount and air mass, temperature, rpm, cooling temperature etc.) which the ECU, depending on the programming, uses to carry out the necessary calculations and make the different system actuators work (injectors, coils, air flow valve, electrofan, etc). Input and output signals can be adjusted independently. Nevertheless, to avoid malfunctions (unlikely) on the injected system, an AUT mode has been implemented where the sensor signals evolves depending on the programmed algorithm thus allowing the student to quickly begin to understand how the injection system works. Similarly, it incorporates the auto-diagnosis system which alongside the DD-Car software allows the student to become familiar with auto-diagnosis techniques.

FEATURES

Technical characteristics

- Stand-alone equipment that incorporates the simulation of the following sensors and actuators:

- SENSORS: Air mass sensor, air admission temperature, crankshaft position, camshaft position, accelerator pedal position, coolant temperature, wide band Lambda sensor, absolute pressure sensor and vibration sensor.

- ACTUATORS: Gas injectors, gas valves, spark plugs, Turbo electrovalve and MAL (Malfunction Indicator Lamp).

- Sensor and actuator communication with the ECU by different types of signal; analogue, digital, multiplexing buses CAN and LIN.

- Testing points protected against possible incorrect manipulations, for carrying out measurements at the different points of the circuit.

- Possibility of generating malfunctions in the signal sent by the sensors to the ECU.

- Automatic or individual operation of the sensors (AUT/IND).

- Reprogramming function (Flash ) of the ECU as a Turbo motor or Atmospheric.

- Auto-diagnosis function implemented in the ECU.

- Possibility of disconnecting the sensors/actuators simulated in the panel and of connecting the real sensors/ actuators of the ADA303 and ADA305 applications.

- Stand-alone equipment that incorporates the simulation of the following sensors and actuators: